Home / Magnetic Drive Pumps

navigation

Contact Person

Factory Add: Hongshan Farm, Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang, China

subscription

QR code

Magnetic drive pumps are sealless centrifugal pumps that use a coaxial magnetic coupling to transmit torque to an impeller. They are energy efficient and can circulate a variety of fluids including acids, caustics, and oils. Magnetic drive pumps (like most sealless pumps) have a higher capital cost than comparable centrifugal pumps, but offer reduced operating costs due to the lack of seal replacement, cleanup, waste, and downtime. They are particularly useful for transporting hazardous or expensive chemicals because there is no mechanical seal, eliminating the possibility of leakage or failure due to an obstruction.

Magnetic drive pumps are sealless centrifugal pumps that use a coaxial magnetic coupling to transmit torque to an impeller. They are energy efficient and can circulate a variety of fluids including acids, caustics, and oils. Magnetic drive pumps (like most sealless pumps) have a higher capital cost than comparable centrifugal pumps, but offer reduced operating costs due to the lack of seal replacement, cleanup, waste, and downtime. They are particularly useful for transporting hazardous or expensive chemicals because there is no mechanical seal, eliminating the possibility of leakage or failure due to an obstruction.

All pumps are designed to operate on either a dynamic or positive displacement principle. Dynamic pumps utilize fluid momentum and velocity to generate pump pressure while positive displacement pumps use expanding and contracting cavities to move fluids. Dynamic pumps produce a variable flow suited for generating high flow rates with low viscosity fluids, while positive displacement pumps produce a constant flow suited for producing high pressures (and low flow rates) with high viscosity fluids.

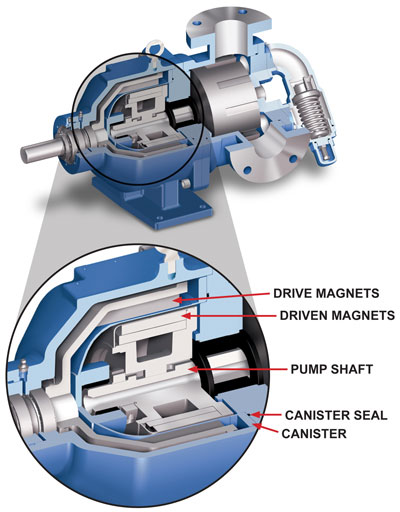

Magnetic drive pumps use magnets to generate movement. These magnets are mounted on a carrier or drive assembly and are driven by a standard electric motor. For dynamic pumps, this drive assembly typically moves an impeller; for positive displacement pumps, it moves a mechanism which expands and contracts a cavity. The drive assembly consists of two separate rings of permanent magnets. The outer set moves the inner set via a rotating magnetic field, which in turn drives the pumping mechanism.

This image from Viking Pumps shows a typical arrangement of the drive assembly in a rotating shaft magnetic drive pump:

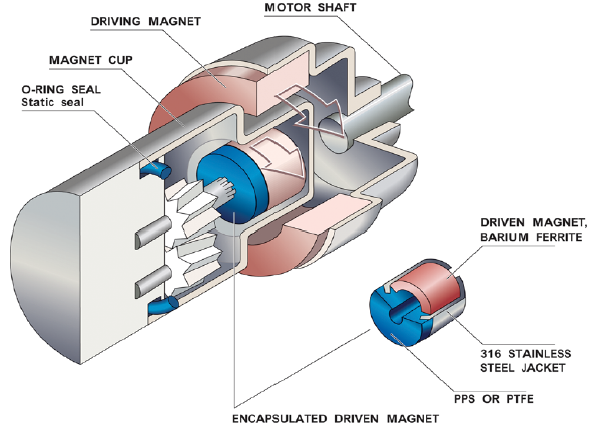

This image (from MicroPump, Inc.) shows asimilar configuration, this one of a magnetic drive gear pump:

Image Credit: Micropump, Inc.

Most magnetic drive pumps are centrifugal pumps (a subset of dynamic pumps), although there are also positive displacement magnetic drive pumps (like the gear pump pictured above). Centrifugal pumps utilize one or more impellers to generate fluid velocity. To learn more about how centrifugal pumps function, visit the Centrifugal Pump Selection Guide page on Engineering360.

There are two basic types of magnetic drivepumps: rotating shaft and stationary shaft.

Rotating shaft magnetic drive pumps are designed for heavy-duty applications.They are usually made of metal, which provides the best strength, temperature,and pressure ratings. The rotating shaft increases the complexity of thepump, meaning more parts are required. More parts means more maintenance andhigher costs.

Stationary shaft magnetic drive pumps have fixed shafts and the drivenmagnets move an entire are designed for light to medium-duty applications. Theyare usually made of non-metallic components (such as ceramics andplastics) which generally provide good corrosion resistance but have a limitedtemperature range up to 200-250°F. The stationary shaft decreases thecomplexity of the pump, meaning less parts are required, simplifyingmaintenance and reducing cost.

The primary specifications to consider when selecting magnetic pumps are flowrate, pump head, pressure, horsepower, power rating, outlet diameter, and operating temperature. The Pump Flow page on Engineering360 provides more information on the significance of these specifications.

When considering using magnetic drive pumpsfor a particular application, there are a number of factors specificto these pumps that should be considered.

Conventional pumps, bearings are typicallylocated away from the pumped media and are lubricated with other materials.Conversely, the bearings on the impeller shaft of magnetic drive pumps arelubricated by the pumpage itself. Therefore low flow, dry running, suspendedsolids, or media with poor lubrication qualities all can affect thereliability and lifetime of these bearings, and should be taken into accountwhen considering this type of pump.

The magnets in a magnetic drive pumpcan demagnetize if exposed to temperatures above their upperlimit. To avoid failure during high temperature applications, usersshould avoid dry running and other conditions that could causeunaccounted or unnecessary heat gain within the pump.

All magnetic couplings arerated for a maximum torque. Beyond this point the magnets operate at reducedspeeds; a state known as "decoupling". Operation in this statecan permanently demagnetized the magnets, making these pumpsespecially vulnerable to variable operating conditions resulting in highpower demands. To prevent decoupling, power monitors should beused for most applications involving magnetic drive pumps.